BG Drilling’s CCT: Continuous Coring Tool

Summary:

BG Drilling introduces its newest innovation to rival Norwegian technology.

BG Drilling, founded by Associate Prof. Shteryo Lyomov, PhD and Grigor Topev, MSc, is a trusted partner in the mineral exploration field with a goal to impact the directional drilling industry. Hailing from a rich tradition of innovation, the company’s mission is to provide efficient and cost-effective solutions for field operations.

BG Drilling is introducing the Continuous Coring Tool (CCT), the first mechanically operated directional core drilling (DCD) system globally. The CCT is designed for complex drilling plans and is capable of operating up to depths of 3000 m. The company is further working on redesigning the CCT to allow for B-size coring and accommodating other main drilling hole sizes.

The company focuses on mechanically-operated tools, like the CWT and CCT, due to their ability to overcome challenges encountered by other systems in deep drilling. The mechanical tools, along with other elements

BG Drilling was founded fifteen years ago by Associate Prof. Shteryo Lyomov, PhD and Grigor Topev, MSc, who had previous experience at the leading company Devico in Norway (now part of Imdex). Their goal was to make a significant impact in the directional drilling industry. Inspired by Bulgaria’s history of specialized R&D in in-the-hole tools during the socialist era, the company has built upon a legacy of innovation. This legacy, dating back to the seventies and eighties, includes notable Bulgarian achievements such as the invention and patenting of the first directional coring tool, core barrel’s roller latch system, bottom-hole shock absorber, and retrievable core bit. Leveraging this rich tradition and expertise, BG Drilling has established itself as a trusted partner in the mineral exploration field, earning recognition for its commitment to excellent field service from both clients and competitors. The company’s mission has always been clear: to provide efficient and cost-effective tools for field operations. These core values are reflected in the company’s culture and its flagship line of tools, the CWT range.

According to Grigor Topev, the company has chosen to steer clear of competing directly with coring technology for a long time, following traditional ethical practices. However, as the industry has changed with the introduction of new competitors and mergers, the company is now prepared to demonstrate its full capabilities.

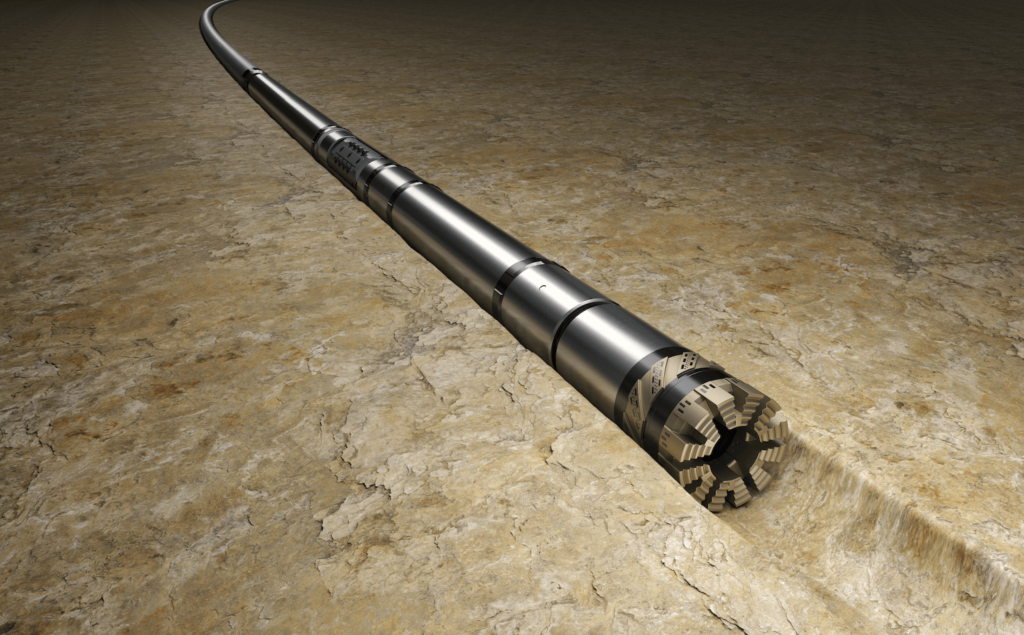

Expanding on the achievements of the CWT, BG Drilling Solutions is excited to introduce the Continuous Coring Tool (CCT) – the first ever mechanically operated directional core drilling (DCD) system in the world, and the second one in terms of operational principle.

The purpose of the Continuous Coring Tool is to drill and retrieve core samples while controlling the direction of the hole. Similar to a standard wireline system, the core can be collected using an inner tube and overshot. The main feature of the CCT system is the company’s CWT technology, which includes the highly praised Roller Pad. This spring-operated mechanism effectively locks the stationary part of the tool, ensuring consistent directional control during drilling. The use of rollers in this unique design reduces axial friction, resulting in improved efficiency compared to other DCD systems.

The CCT is an efficient and highly productive tool, with an average output of 15 to 20 m (49-66 ft) per shift. It is specifically designed for intricate drilling plans, providing consistent deviations over extended distances of about 9° per 30 m (98 ft). This essential instrument is well-suited for projects that require complex deviations and is capable of operating at depths of up to 3000 m (9843 ft). It can be used for a variety of drilling tasks, including accurate hole navigation and branching, making it a valuable asset for vital projects in industries such as mineral exploration, geotechnical, and tunneling.

The current size option for the CCT is N, with impressive compactness at 4.5 m (14.77 ft) in length and a weight of 45 kg (99.2 lb). This makes it ideal for use in confined spaces, ensuring safety and efficiency. Its core run yields a 3 m (9.84 ft) core with a diameter of 32 mm (1.26 in).

A CCT redesign is currently in progress to allow for B-size coring and is expected to be launched in 2025. BG Drilling Solutions is also working on versions of the CCT that can accommodate the other two main drilling hole sizes, B and H, in order to increase the tool’s flexibility and potential use in different drilling situations.

The focus at BG Drilling is on using mechanically-operated tools due to their ability to overcome challenges that other systems may encounter. When it comes to deep drilling, there are often problems with hydraulic efficiency or instability, which can affect the performance of hydraulic-dependent tools. This is especially true for systems like steerable bottom-hole motors, which require large amounts of drilling fluid and may face issues such as stalling or reduced penetration at greater depths. Furthermore, these systems require additional mud pumps and smaller drill rods, leading to added complexity and potential disadvantages. In contrast, mechanically-operated systems like the CWT and CCT are not limited by these factors and consistently perform well, particularly at depths below 2000 m (6562 ft), where their reliability and efficiency are even more evident. The reliability of existing DCD systems may also be compromised, resulting in directional errors, whereas the CWT and CCT function independently from these limitations.

Our primary aim has continuously been conducting research and development to provide the industry with cutting-edge and economical solutions. The mechanical tools serve as a means for significant enhancements in current technology, possessing a strong and dependable nature. When combined with other elements, they enable a considerable decrease in usage costs, resulting in a service cost reduction of almost 50% compared to the present DCD systems, as stated by Associate Prof. Shteryo Lyomov.

In addition to the highly anticipated introduction of the CCT, BG Drilling is delighted to announce another revolutionary patent-pending progress known as the CWT Dual Mode (CWT DM). This breakthrough sets a new standard in the industry by introducing the first-ever feature for adjusting down-the-hole dogleg severity, a feat unmatched by any other in the field. This advancement simplifies tripping operations, greatly enhancing the operational effectiveness of the CWT.

BG Drilling has created a classification system to aid clients in selecting the appropriate directional tools for their projects, with three types of directional tools available on the market. This system categorizes directional drilling tasks into three groups, taking into account the deviation needed per intervention. This facilitates a better understanding of the tools’ capabilities and simplifies the selection process for specific drilling needs. By using this approach, clients can make informed decisions and choose tools that align perfectly with the specific requirements of their drilling projects, until standard diamond coring operations can resume.

Mid-Range Deviations: Typically falling within the range of 5 to 15°, these adjustments usually entail realigning paths that have strayed greatly from the intended course or carrying out assignments with nearby targets in branching operations. The CWT DM is highly adaptable and can modify DLS without causing disruptions, making it an invaluable resource that balances accuracy with the requirement for minimal intervention.

Long-Range Deviations: When deviations reach beyond 15°, the difficulty increases and calls for specialized tools that can handle intricate steering and longer correction routes. This particular category requires advanced engineering and operational expertise, aspects in which BG Drilling’s CCT, downhole motors, and other DCD systems excel, guaranteeing effective navigation of even the most challenging deviations.

It is worth mentioning that tools such as the CWT, which are designed for short-range deviations, excel in both the other two categories. However, their efficiency may be reduced due to the higher frequency of short interventions, resulting in more tripping. In contrast, more sophisticated tools have the ability to handle both short and mid-range categories, but they come at a higher price. When core retrieval is necessary, the selection based on deviation categories is not applicable.

The Continuous Coring Tool (CCT) is the first ever mechanically operated directional core drilling (DCD) system in the world. It is designed to drill and retrieve core samples while controlling the hole’s direction. The CCT system uses the company’s CWT technology, including the patented Roller Pad, for consistent directional control during drilling. The CCT is efficient, highly productive, and well-suited for complex drilling tasks.

The CCT is capable of operating at depths of up to 3000 m (9843 ft) and provides consistent deviations over extended distances. It is designed for intricate drilling plans and can be used for accurate hole navigation and branching. The CCT has an average output of 15 to 20 m (49-66 ft) per shift and yields a 3 m (9.84 ft) core with a diameter of 32 mm (1.26 in).

The CWT Dual Mode (CWT DM) is a revolutionary patent-pending progress by BG Drilling. It sets a new industry standard by introducing the first-ever feature for adjusting down-the-hole dogleg severity. This advancement simplifies tripping operations and enhances the operational effectiveness of the CWT.

BG Drilling’s classification system categorizes directional drilling tasks into three groups based on the deviation needed per intervention: Short-Range Deviations, Mid-Range Deviations, and Long-Range Deviations. This system helps clients understand the capabilities of the tools and simplifies the selection process for specific drilling needs.